Characteristic advantages

Good corrosion resistance (suitable for freshwater and air environments)

Excellent ductility and processability

High conductivity

Smooth mesh surface, golden color, beautiful and generous

Non-magnetism Material

Common specifications

Material: stainless steel wire 304, 304L, 316, 316L, 310, 314, 410, 430.

Weaving type: plain weave, twill weave, dutch twill.

Serial Number | Mesh Count | Wire Diameter | Mesh Hole Size | Thickness | Maximum Width | Opening rate | ||

Inches | mm | Inches | mm | mm | mm | % | ||

SS-1 | 1 × 1 | 0.157 | 4 | 0.84 | 21.4 | 8 | 2000 | 71 |

SS-2 | 2 × 2 | 0.118 | 2.5 | 0.38 | 10.2 | 5 | 2000 | 64.5 |

SS-3 | 3 × 3 | 0.079 | 2 | 0.25 | 6.4 | 4 | 2000 | 58 |

SS-4 | 4 × 4 | 0.063 | 1.6 | 0.187 | 4.75 | 3.2 | 2000 | 56 |

SS-5 | 4 × 4 | 0.047 | 1.2 | 0.203 | 5.15 | 2.4 | 2000 | 65.8 |

SS-6 | 5 × 5 | 0.055 | 1.4 | 0.14 | 3.68 | 2.8 | 2000 | 52.5 |

SS-7 | 6 × 6 | 0.047 | 1.2 | 0.12 | 3.03 | 2.4 | 2000 | 51.3 |

SS-8 | 8 × 8 | 0.43 | 1.1 | 0.08 | 2.08 | 2.2 | 2000 | 42.8 |

SS-9 | 10 × 10 | 0.039 | 1 | 0.06 | 1.54 | 2 | 2000 | 36.8 |

SS-10 | 10 × 10 | 0.02 | 0.51 | 0.08 | 2.03 | 1.02 | 2000 | 63.9 |

SS-11 | 12 × 12 | 0.023 | 0.584 | 0.06 | 1.52 | 1.17 | 2000 | 52.2 |

SS-12 | 12 × 12 | 0.02 | 0.508 | 0.063 | 1.6 | 1.02 | 2000 | 57.6 |

SS-13 | 14 × 14 | 0.023 | 0.584 | 0.048 | 1.22 | 1.17 | 2000 | 45.7 |

SS-14 | 14 × 14 | 0.02 | 0.508 | 0.051 | 1.3 | 1.02 | 2000 | 51.7 |

SS-15 | 16 × 16 | 0.018 | 0.457 | 0.0445 | 1.13 | 0.91 | 2000 | 50.7 |

SS-16 | 18 × 18 | 0.017 | 0.432 | 0.0386 | 0.98 | 0.86 | 2000 | 48.2 |

SS-17 | 20 × 20 | 0.02 | 0.508 | 0.03 | 0.76 | 1.02 | 2000 | 35.9 |

SS-18 | 20 × 20 | 0.016 | 0.406 | 0.034 | 0.86 | 0.81 | 2000 | 46.1 |

SS-19 | 24 × 24 | 0.014 | 0.356 | 0.0277 | 0.7 | 0.71 | 2000 | 43.9 |

SS-20 | 30 × 30 | 0.013 | 0.33 | 0.0203 | 0.52 | 0.66 | 2000 | 37.4 |

SS-21 | 30 × 30 | 0.012 | 0.305 | 0.0213 | 0.54 | 0.61 | 2000 | 40.8 |

SS-22 | 30 × 30 | 0.009 | 0.229 | 0.0243 | 0.62 | 0.46 | 2000 | 53.3 |

SS-23 | 35 × 35 | 0.011 | 0.279 | 0.0176 | 0.45 | 0.56 | 2000 | 38.1 |

SS-24 | 40 × 40 | 0.01 | 0.254 | 0.015 | 0.38 | 0.51 | 2000 | 35.9 |

SS-25 | 50 × 50 | 0.009 | 0.229 | 0.011 | 0.28 | 0.46 | 2000 | 30.3 |

SS-26 | 50 × 50 | 0.008 | 0.203 | 0.012 | 0.31 | 0.41 | 2000 | 36.5 |

SS-27 | 60 × 60 | 0.0075 | 0.191 | 0.0092 | 0.23 | 0.38 | 2000 | 29.8 |

SS-28 | 60 × 60 | 0.007 | 0.178 | 0.0097 | 0.25 | 0.36 | 2000 | 34.1 |

SS-29 | 70 × 70 | 0.0065 | 0.165 | 0.0078 | 0.2 | 0.33 | 2000 | 30 |

SS-30 | 80 × 80 | 0.0055 | 0.14 | 0.007 | 0.18 | 0.28 | 2000 | 31.6 |

SS-31 | 80 × 80 | 0.0047 | 0.12 | 0.0077 | 0.197 | 0.24 | 2000 | 38.6 |

SS-32 | 90 × 90 | 0.005 | 0.127 | 0.0061 | 0.16 | 0.25 | 2000 | 31.1 |

SS-33 | 100 × 100 | 0.0045 | 0.114 | 0.0055 | 0.14 | 0.23 | 2000 | 30.4 |

SS-34 | 100 × 100 | 0.004 | 0.102 | 0.006 | 0.15 | 0.2 | 2000 | 35.4 |

SS-35 | 100 × 100 | 0.0035 | 0.089 | 0.0065 | 0.17 | 0.18 | 2000 | 43.1 |

SS-36 | 110 × 110 | 0.004 | 0.1016 | 0.0051 | 0.1295 | 0.2 | 2000 | 31.4 |

SS-37 | 120 × 120 | 0.0037 | 0.094 | 0.0046 | 0.1168 | 0.19 | 2000 | 30.7 |

SS-38 | 150 × 150 | 0.0026 | 0.06 | 0.0041 | 0.1041 | 0.12 | 2000 | 40.2 |

SS-39 | 160 × 160 | 0.0025 | 0.0635 | 0.0038 | 0.0965 | 0.13 | 2000 | 36.4 |

SS-40 | 180 × 180 | 0.0023 | 0.0584 | 0.0033 | 0.0838 | 0.12 | 2000 | 34.7 |

SS-41 | 200 × 200 | 0.0021 | 0.0533 | 0.0029 | 0.0737 | 0.11 | 2000 | 33.7 |

SS-42 | 250 × 250 | 0.0016 | 0.04 | 0.0024 | 0.061 | 0.08 | 2000 | 36.5 |

SS-43 | 270 × 270 | 0.0016 | 0.04 | 0.0021 | 0.054 | 0.08 | 2000 | 33 |

SS-44 | 300 × 300 | 0.0016 | 0.04 | 0.0018 | 0.0446 | 0.08 | 2000 | 27.8 |

SS-45 | 325 × 325 | 0.0014 | 0.0356 | 0.0017 | 0.0432 | 0.07 | 2000 | 30.1 |

SS-46 | 400 × 400 | 0.0011 | 0.03 | 0.0015 | 0.033 | 0.06 | 1600 | 27.4 |

SS-47 | 500 × 500 | 0.001 | 0.0254 | 0.001 | 0.0254 | 0.05 | 1500 | 25 |

SS-48 | 635 × 635 | 0.0008 | 0.0203 | 0.0008 | 0.0203 | 0.04 | 1300 | 25 |

Application area

1. Industrial filtration

Liquid, gas, and slurry filtration in industries such as petroleum, chemical, and metallurgical

2. Architecture and Decoration

Curtain wall decoration net, elevator decoration net, ceiling, wall decoration

3. Food processing

Food grade sieve, drying rack, barbecue mesh, conveyor belt

4. Mining and screening

Screening and grading of sand, ore, coal, aggregates, etc

5. Electronic and electromagnetic shielding

Electromagnetic wave shielding and electrostatic conductivity in precision electronic devices

6. Aerospace and Military Industry

High precision filtration in aviation fuel systems and hydraulic systems

7. Agriculture and Environmental Protection

Horticultural pest control net, livestock breeding net, aquaculture net

8. Laboratory and Pharmaceutical Industry

Experimental filtration, powder screening, and cleaning basket

Application area | Recommended materials | Common mesh range |

Industrial filtration | 304, 316L | 10–200 mesh |

Architectural decoration | 304, 316 | 10–80 mesh |

food processing | 304(食品级) | 10–50 mesh |

Ore screening | 201, 304 | 1–30 mesh |

Laboratory/Pharmaceutical | 316L | 80–400 mesh |

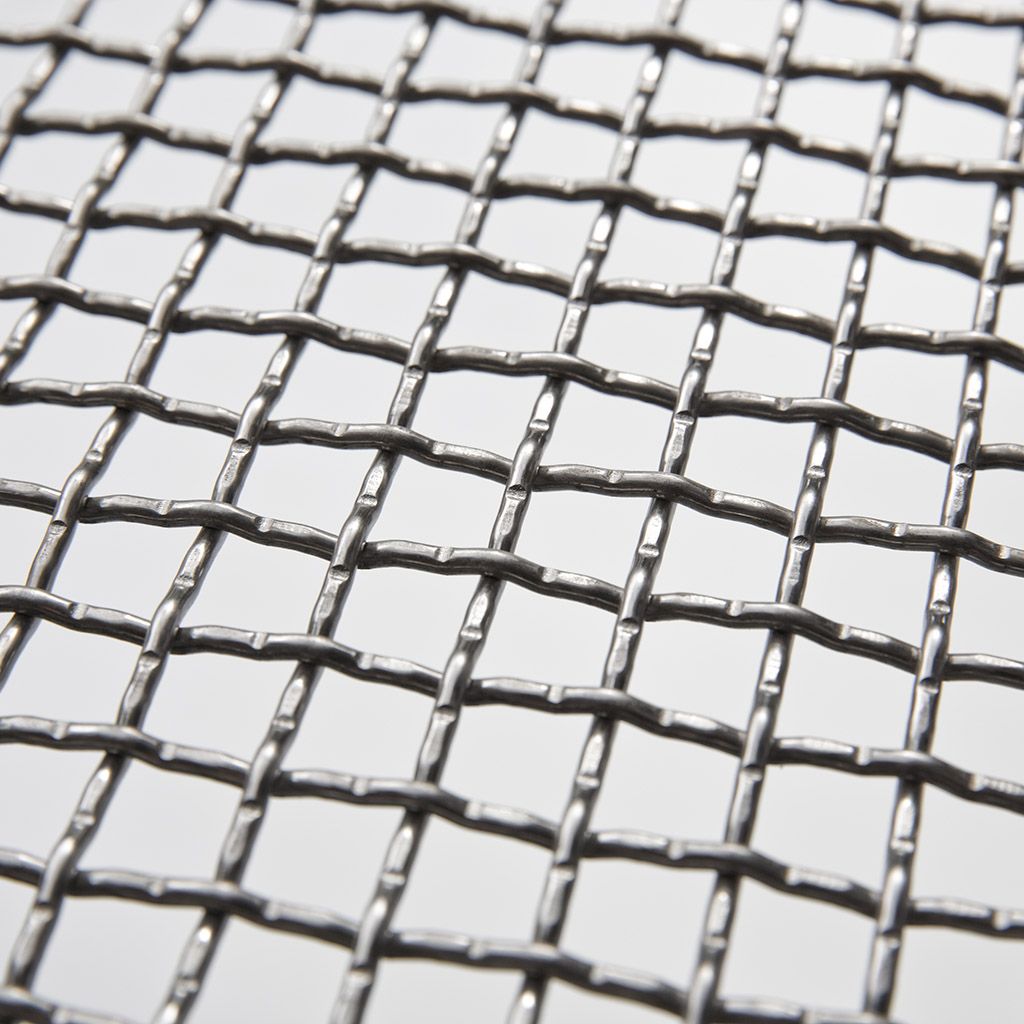

The Stainless Steel Woven Wire Mesh is made from premium stainless steel wire, combining high tensile strength and excellent corrosion resistance. This mesh is widely used across industries such as chemical processing, food and beverage, mining, and construction for filtration, screening, and protective applications.

With a precise weaving pattern, the mesh provides uniform openings that enable efficient particle filtration and separation while maintaining structural stability. Its corrosion-resistant properties make it suitable for harsh environments, including exposure to moisture, chemicals, and temperature fluctuations.

The stainless steel material ensures long service life with minimal maintenance, reducing operational costs. The mesh can be customized in various wire diameters, mesh sizes, and weaving styles to meet specific project requirements.

Common uses include water filtration systems, industrial sieves, protective guards, and reinforcement in composite materials. Its robust construction and versatility make it a reliable choice for both heavy-duty industrial use and fine filtration needs.

Manufactured under strict quality control standards, our stainless steel woven wire mesh guarantees consistent performance, durability, and adaptability for a wide range of applications.

Our Stainless Steel Woven Wire Mesh offers a perfect combination of strength, corrosion resistance, and flexibility. Crafted from high-quality stainless steel wire, this mesh is designed for applications requiring reliable filtration, screening, and reinforcement.

The mesh’s uniform weave pattern ensures consistent aperture sizes, providing efficient filtration performance across a variety of industrial processes. Its excellent corrosion resistance allows it to function effectively in harsh chemical, marine, and outdoor environments without rusting or degrading.

Widely used in industries such as pharmaceuticals, food processing, mining, and environmental engineering, the stainless steel woven wire mesh provides dependable mechanical strength and dimensional stability. It can be customized to specific mesh counts, wire diameters, and weaving styles to match different filtration or structural requirements.

Its durability reduces downtime and maintenance costs, making it a cost-effective choice for long-term industrial use. The mesh is also easy to clean and maintain, ensuring sustained filtration efficiency.

Produced with advanced manufacturing processes and rigorous quality control, our stainless steel woven wire mesh delivers outstanding performance and longevity for demanding industrial applications.

Please leave us a message and we will get back to you shortly.